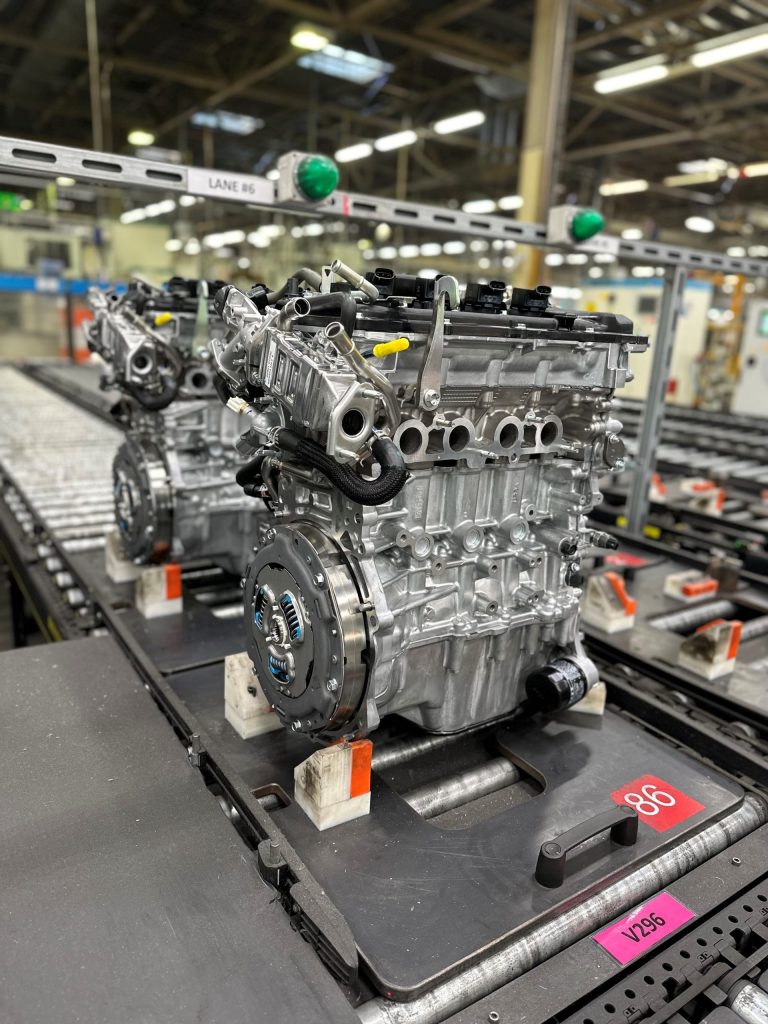

Toyota is investing €541,000 (approx. £465,000) in upgrading its UK engine plant, Toyota Manufacturing UK (TMUK), to assist in the beginning of European production of its fifth generation hybrid electric powertrain. TMUK’s factory in Deeside, North Wales is being refurbished for the assembly line of the 1.8-litre petrol engine incorporated in the new system.

The newest generation of Toyota’s hybrid technology will be introduced in the new Corolla range including the Hatchback and Touring Sports models built by TMUK at Burnaston in Derbyshire as well as the new Corolla Saloon, produced in Turkey. The fifth generation of powertrain offers improved performance and drivability with lighter and more compact electric motors. Both 1.8 and 2.0-litre powertrains are available, with the 1.8 offering lower CO2 emissions. The total system output for the new 1.8 powertrain is 138bhp, allowing for a 0-62mph acceleration time reduced by 1.7 seconds to 9.2 seconds.

Toyota has also invested €77m (approx. £70m) in Toyota Motor Manufacturing Poland (TMMP) to be used as the European centre for the production of the hybrid electric transmission, which includes motor-generators and electrical components. The fourth generation hybrid electric system produced by TMUK and TMMP since 2016 and 2018 respectively, has been replaced by the new generation technology. During this time, Toyota has increased their investment in hybrid technology and saw the overall electrified mix in its total European new car sales increase from 30% to 66%.

Marvin Cooke, Toyota Motor Europe Executive Vice President for Manufacturing said, “Toyota’s affordable, low emission hybrid electrified vehicles have an important role to play in our pan-European multi-technology strategy, which seeks to help everyone reduce their carbon emissions. Hybrid technology now features in 85% and 70% of the engines and transmissions produced at TMUK and TMMP respectively, which is a reflection of the ever-growing customer demand for Toyota hybrid products.”