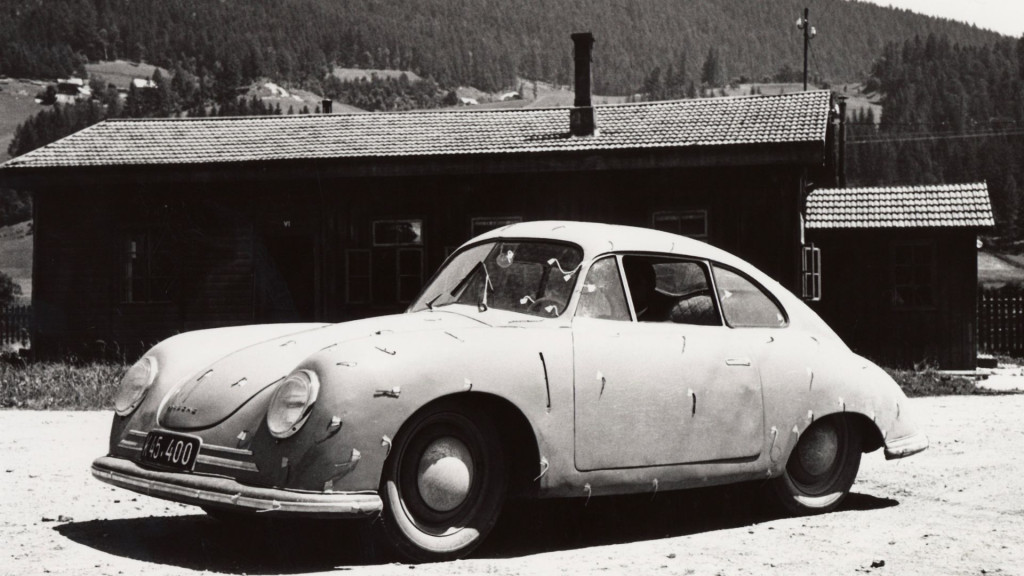

Porsche’s first sports cars featured lightweight aluminum body panels, but it was nature’s own material that allowed for their iconic shape.

The Porsche 356 had bodywork formed by hammering and hand-rolling panels into shape, with a wooden frame used to ensure proper alignment.

That frame still exists in good condition at the Porsche Automuseum in Gmünd, Austria, where the first Porsche production cars were completed. The frame, sometimes called Holzklopfmodell (or “hammered wooden frame” in German), served as the exact model for factory workers to shape and fit the aluminum panels. This time-consuming process required multiple attempts to ensure that doors and fenders fit perfectly to the frame. According to Porsche, this process took at least 90 hours.

Porsche 356/2 coupe manufactured in Gmünd, Austria

Handmade bodywork was a characteristic feature of the earliest Porsche cars built in Austria. From 1948, Porsche produced 52 cars in Gmünd, including 44 coupes and eight convertibles, along with the eight to 10 super light (SL) bodies that were later completed by Porsche’s racing department in Stuttgart between 1951 and 1952.

When production shifted to Germany in 1949, Porsche switched to mechanized manufacturing processes and steel bodies, discarding hand-formed aluminum for special vehicles like the 16 lightweight 356 America Roadsters. A new wooden frame replaced the original.

As steel is much harder than aluminum, Porsche began using presses to form body panels to produce cars at a faster rate. To this day, the Porsche 356 wood frame remains a testament to the automaker’s early days.